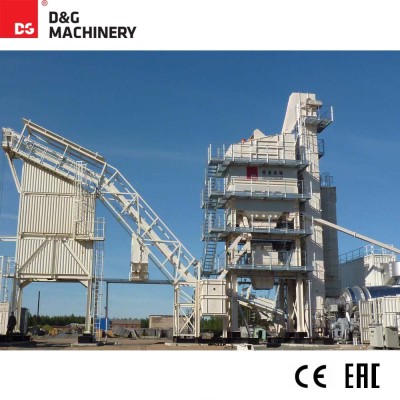

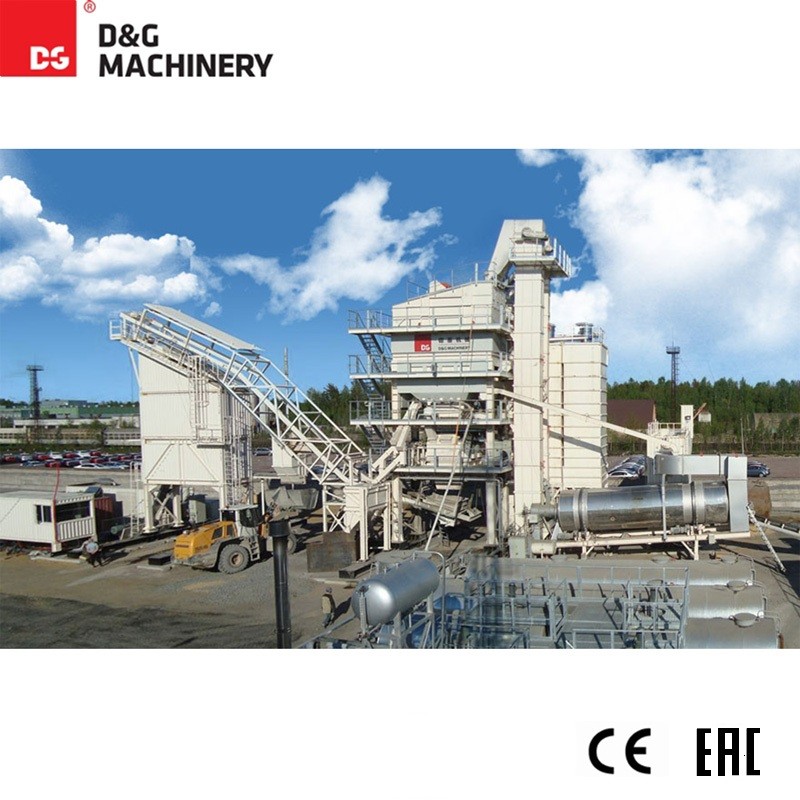

D&G Compact Series with used asphalt mixing plant

Detail Information

More Detail ->

THE TECHNICAL DATA

| MODEL | DG2000AC | DG2500AC | DG3000AC | |

| Rated Production Capacity | 180 t/h | 200 t/h | 240 t/h | |

| Cold Feeder Bin | Number × Volume | 5 × 10 m³ | 5 × 10 m³ | 5 × 18 m³ |

| Dryer Drum | Diameter Ø | ø 2.2 m | ø 2.2 m | ø 2.5 m |

| Length | 9 m | 9 m | 9 m | |

| Fuel Type | Diesel / Heavy Oil / Nature Gas | |||

| Drying Capacity | ||||

| – Moisture Content 3% | 220 t/h | 220 t/h | 300 t/h | |

| – Moisture Content 5% | 180 t/h | 180 t/h | 240 t/h | |

| Bag House | Dust Filtering Method | (1st Stage) Pre-separator + (2nd Stage) Bag Filtering House | ||

| Main Tower | Screening | 5 | 5 | 5 |

| Screening Area | 24.2 m² | 28.1 m² | 28.1 m² | |

| Hot Bin Quantity | 5 + 1 | 5 + 1 | 5+1 | |

| Hot Bin Overall Volume | 21 m³ | 40 m³ | 40 m³ | |

| Aggregates Weighing | 2000 kg | 2500 kg | 3000 kg | |

| Filler Weighing | 200 kg | 300 kg | 400 kg | |

| Bitumen Weighing | 200 kg | 300 kg | 400 kg | |

| Mixing Power | 2 × 37 kW | 2 × 45 kW | 2 × 45 kW | |

| Mixing Capacity | 2000 kg | 3000 kg | 3000 kg | |

| Filler Scaling & Feeding | Vari-Frequency Screw, Compelled and Well-Distributed Feeding Design. | |||

| Bitumen Scaling & Feeding | Dynamic 2-Stage Measurement, High Pressure Uniformly Spray. | |||

| Mixing | 2 Horizontal Mixing Shafts, Dual-Motor Driven with Synchronous Reducer. | |||

| Control System | • DGLeap Control System 2.0ontrol System 2.0 • Large Screen Industrial Computer • PLC Touch Screen HMI • Laser Printer • Air-Conditioned Control Cabin | |||

| Environment Index | • Dust Density⩽20mg/Nm³ • Ringelmann Blackness Class 1 • Noise in Control Cabin ⩽70dB | |||

* The above specifications are for reference only. D&G Machinery reserves the right to make changes in engineering, design and improvement at any time without prior notice or obligation.

PRODUCT DISPLAY

Please send your message to us

- Tel

- *Title

- *Content