Home / All / D&G Asphalt Mixing Plant Series /

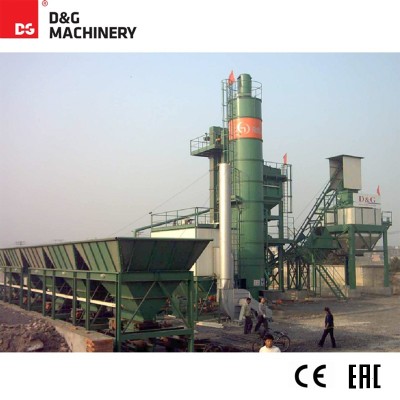

Multiple models asphalt batch mix plant in bituminous pavement

Multiple models asphalt batch mix plant in bituminous pavement

Detail Information

Multiple models asphalt batch mix plant in bituminous pavement

THE TECHNICAL DATA

| MODEL | DG1300 | DG1500 | DG2000 | DG2500 | DG3000 | DG4000 | DG5000 | |

| Rated Production Capacity | 123 t/h | 140 t/h | 180 t/h | 200 t/h | 240 t/h | 320 t/h | 400 t/h | |

| Cold Feeder Bin | Number × Volume | 4 × 10 m³ | 5 × 10 m³ | 5 × 10 m³ | 5 × 10 m³ | 5 × 18 m³ | 6 × 18 m³ | 6 × 18 m³ |

| Dryer Drum | Diameter Ø | ø 1.9 m | ø 1.9 m | ø 2.2 m | ø 2.2 m | ø 2.5 m | ø 2.8 m | ø 3.0 m |

| Length | 8.5 m | 8.5 m | 9 m | 9 m | 9 m | 12 m | 12 m | |

| Fuel Type | Diesel / Heavy Oil / Nature Gas / LPG / Coal | |||||||

| Drying Capacity | ||||||||

| – Moisture Content 3% | 170 t/h | 170 t/h | 220 t/h | 220 t/h | 300 t/h | 390 t/h | 450 t/h | |

| – Moisture Content 5% | 120 t/h | 120 t/h | 180 t/h | 180 t/h | 240 t/h | 320 t/h | 400 t/h | |

| Bag House | Dust Filtering Method | (1st Stage) Pre-separator + (2nd Stage) Bag Filtering House | ||||||

| Main Tower | Screening | 4 | 5 | 5 | 5 | 5 | 6 | 6 |

| Screening Area | 10.1 m² | 24.2 m² | 24.2 m² | 28.1 m² | 38.4 m² | 58.7 m² | 69 m² | |

| Hot Bin Quantity | 4 + 1 | 5 + 1 | 5 + 1 | 5 + 1 | 5+1 / 6+1 | 6 + 1 | 6 + 1 | |

| Hot Bin Overall Volume | 21 m³ | 21 m³ | 21 m³ | 40 m³ | 45 m³ | 75 m³ | 80 m³ | |

| Aggregates Weighing | 1300 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4200 kg | 5500 kg | |

| Filler Weighing | 130 kg | 150 kg | 200 kg | 300 kg | 400 kg | 500 kg | 800 kg | |

| Bitumen Weighing | 130 kg | 150 kg | 200 kg | 300 kg | 400 kg | 500 kg | 500 kg | |

| Mixing Power | 2 × 18.5 kW | 2 × 30 kW | 2 × 37 kW | 2 × 45 kW | 2 × 45 kW | 2 × 55 kW | 2 × 75 kW | |

| Mixing Capacity | 1300 kg | 2000 kg | 2000 kg | 3000 kg | 3300 kg | 4200 kg | 5500 kg | |

| Filler Scaling & Feeding | Vari-Frequency Screw, Compelled and Well-Distributed Feeding Design. | |||||||

| Bitumen Scaling & Feeding | Dynamic 2-Stage Measurement, High Pressure Uniformly Spray. | |||||||

| Mixing | 2 Horizontal Mixing Shafts, Dual-Motor Driven with Synchronous Reducer. | |||||||

| Control System | • DGLeap Control System 2.0ontrol System 2.0 • Large Screen Industrial Computer • PLC Touch Screen HMI • Laser Printer • Air-Conditioned Control Cabin | |||||||

| Environment Index | • Dust Density⩽20mg/Nm³ • Ringelmann Blackness Class 1 • Noise in Control Cabin ⩽70dB | |||||||

*The above specifications are for reference only. D&G Machinery reserves the right to make changes in engineering, design and improvement at any time without prior notice or obligation.

PRODUCT DISPLAY

Please send your message to us

- Tel

- *Title

- *Content