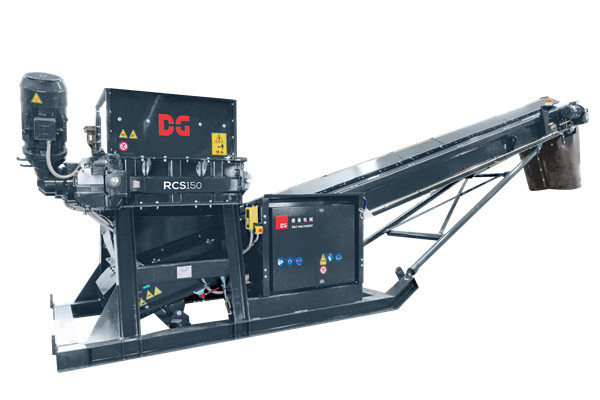

RAP Tooth Roller Type Crushing and Screening Equipment

Recently, the attention of PRIMACH's high-quality RAP tooth roller type crushing and screening equipment was listed.

RAP tooth roller type crushing equipment adopts asymmetric low-speed flexible tooth roller crushing method, which has the following characteristics:

1. It retains the characteristics of tooth roller crushing, and performs shearing, squeezing and bending on the pavement recycled materials, which reduces the impact on the recycled materials compared with jaw breaking and impact breaking, that is, reduces dust emission, and the equipment runs smoothly. Carrying out a crushing effect similar to "kneading" on the recycled materials is to reduce the crushing of large-particle materials. Breaking and squeezing of recycled materials reduces the generation of fine materials, which is also conducive to retaining the original RAP grade ratio.

2. It adopts the differentiated arrangement of crushing tooth rollers, which increases the meshing area of shredding teeth compared with ordinary tooth rollers, so that the maximum crushing particle size of the crusher reaches 80mm, and the crushing efficiency is improved.

3. The low-speed flexible crushing mode is adopted, and the crushing as low as 20 rpm enhances the "kneading" effect of the crushing tooth roller on the material and further reduces the impact on the recycled materials, closer to the concept of flexible crushing, and produces less fine crushed materials.